As introduced in the first part of this series of articles entitled Development of a new topological optimization model to improve the efficiency of components for nuclear fusion, due to the high energy density of the IFMIF DONES accelerator beam some of its components will operate in critical conditions, specially in terms of temperature. Thus, it is necessary for these components to include an integrated cooling system.

Our previous article entitled Advances in the development of the new topological optimization model for the design of cooled components subject to the energy beam of the IFMIF DONES accelerator, dealt with the development of a new topology optimization method for the design of cooling circuits of this type of components, considering fluid dynamics and heat transfer. Here, we go a step further and include lattice-type structures embedded in the circuit to maximize heat transfer.

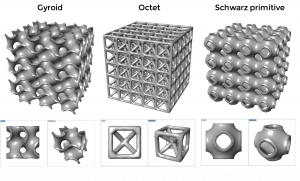

A lattice structure is a construction based on a series of points arranged in a pattern. Figure 1 shows some examples of different lattice structures.

Figure 1 Examples of different lattice structures

These structures offer very interesting possibilities for heat exchange, as they open a double path for heat dissipation. On the one hand, heat is transported from the heated plate through the solid part of the lattice structure by conduction. On the other hand, at the same time it is also dissipated by the coolant flow circulating through the pores. The combination of efficient thermal conduction in the solid parts of the structure and low flow resistance through the pore channels results in a very efficient heat exchange.

The effect of introducing these structures locally into the optimized cooling circuit discussed in our previous article has been studied to maximize heat dissipation.

Figure 2 Addition of lattice structures to the optimized cooling circuit

This way, the effectiveness of these lattice structures as heat dissipators is demonstrated. However, a more in-depth study would be required to find the optimal lattice design parameters, in terms of porosity, permeability, manufacturability, material, etc. for a certain component, for example to be applied on IFMIF-DONES refrigerated parts.

The FusionCAT project with file number 001-P-001722 has been 50% co-financed with €1.960.963,66 by the European Union Regional Development Fund within the framework of the ERDF Operational Program of Catalonia 2014-2020 with the support of Generalitat of Catalonia.